A survey found that 98% of customers say the delivery experience is a key part of their brand loyalty. After all, fast deliveries usually equal happy customers. And with rapid advancements in technology, customers are propelled towards same-day and next-day delivery expectations.

So, what stands in the way of rapid fulfillment and delivery? Disorganized warehouse layouts and inefficient picking are amongst the biggest culprits.

Running a warehouse is all about optimization. Mispicked or difficult-to-locate items slow down order fulfillment. Even worse, when warehouse operatives feel rushed, they’re more likely to make mistakes.

What are you doing to ensure your warehousing is running optimally? Let us explain how to master warehouse efficiency with strategic SKU management.

What Is Strategic SKU Management?

Strategic SKU management is a framework for organizing and processing warehouse inventory. Stock keeping unit (SKU) management uses alphanumeric codes to categorize and track items. These codes enable warehouse operators and fulfillment centers to locate and monitor stock levels in real-time.

Effective SKU management requires tailoring warehousing to your business and its customers. An SKU strategy streamlines tasks such as receiving, scanning, picking, and fulfillment.

What Are SKU Numbers?

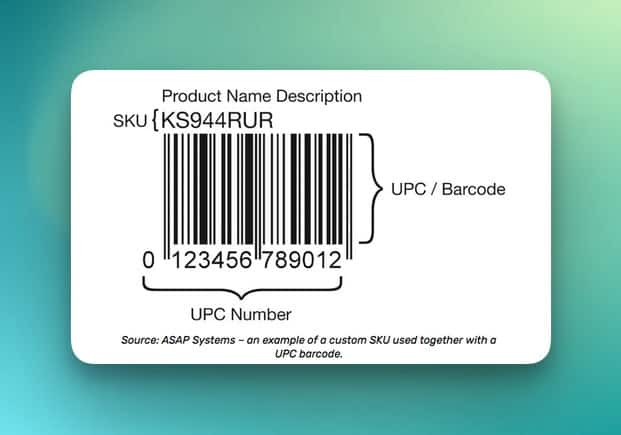

SKUs are typically 8-12 randomly assigned alphanumeric strings of characters. Each retailer uses a system designed to identify items based on characteristics like color, size, and model.

SKU vs UPC

A UPC is a universal product code – a unique string of numbers that identifies a product. A non-profit that maintains global standards for barcode scanning, GS1, generates UPCs.

Unlike a UPC, businesses assign SKU codes to products they sell. For example, a pair of Nike sneakers would be assigned a SKU from a sporting goods store. An online fashion retailer may sell the same sneakers with a SKU assigned from its system.

What Are the Benefits of a SKU Management System?

Using an effective SKU system does more than organize ordering. Many benefits come from using SKU management tactics, including:

- More efficient warehouse layout – arrange items based on order frequency and expiry date.

- Better inventory management – automatic reorder points that prevent stockouts.

- Streamlined order fulfillment – faster, easier workflow for order pickers and packers or 3PL providers.

- Shipment tracking – integrated tracking of every processed order.

- Better customer service – live order tracking and faster refunds.

- Improved store design – optimize store design for a better customer experience and increased sales.

- Loss prevention – track inventory along the supply chain in real-time so nothing goes missing.

- Human error reduction – automate redundant tasks like SKU assignment and inventory accounting.

- Data visualization and warehouse analytics – actionable insights drive informed decision-making and optimize operations.

- Time and money savings – eliminate poor-performing products and stock high-profit.

How to Improve Warehousing With Strategic SKU Management

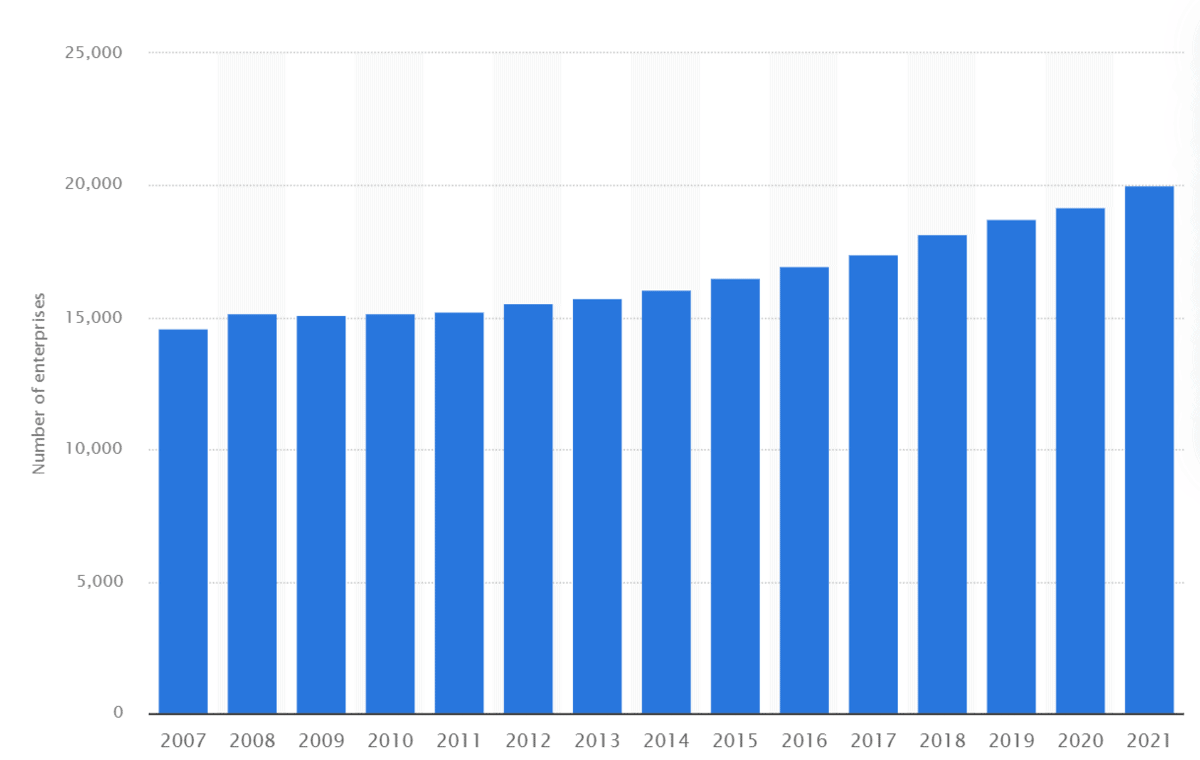

Since 2010, the number of warehousing businesses has steadily risen from under 15,000 to over 20,000 in 2021. As the storage industry continues to grow, efficient operations will stand out from the competition.

A SKU management strategy will give your business the boost it needs to remain competitive.

1. Follow Best Practices for Creating SKUs

If it’s not broken, don’t try to fix it. An effective SKU framework works when you follow the road already paved. Follow the best practices for SKU generation.

Keep It Simple, Standardize

Don’t get clever with SKUs. You may be tempted to develop a complex system that fully describes each item. Instead, focus on three to five characteristics that are useful for categorization. For example, if we look at electric guitars, you can use the make, model, color, and year.

Only use between two and three characters for each descriptive category. You may need three letters to distinguish black (BLK) from blue (BLU). However, two digits are fine for identifying the year of manufacture.

Avoid Confusion

You can avoid input errors and picking confusion by minimizing the use of characters that appear similar. Some examples are capital “I”, lowercase “l” and the number “1”. Another source of confusion is the number ”0” and capital “O.”

In these cases, make it standard to only use one or the other and avoid mistakes.

No Special Characters or Symbols

You will use either “-” or “_” to separate SKU code identifiers. Don’t bother with any special characters such as “%, *, &” and others. Use of these symbols will often disrupt your inventory management system.

2. Group SKUs by Similarities

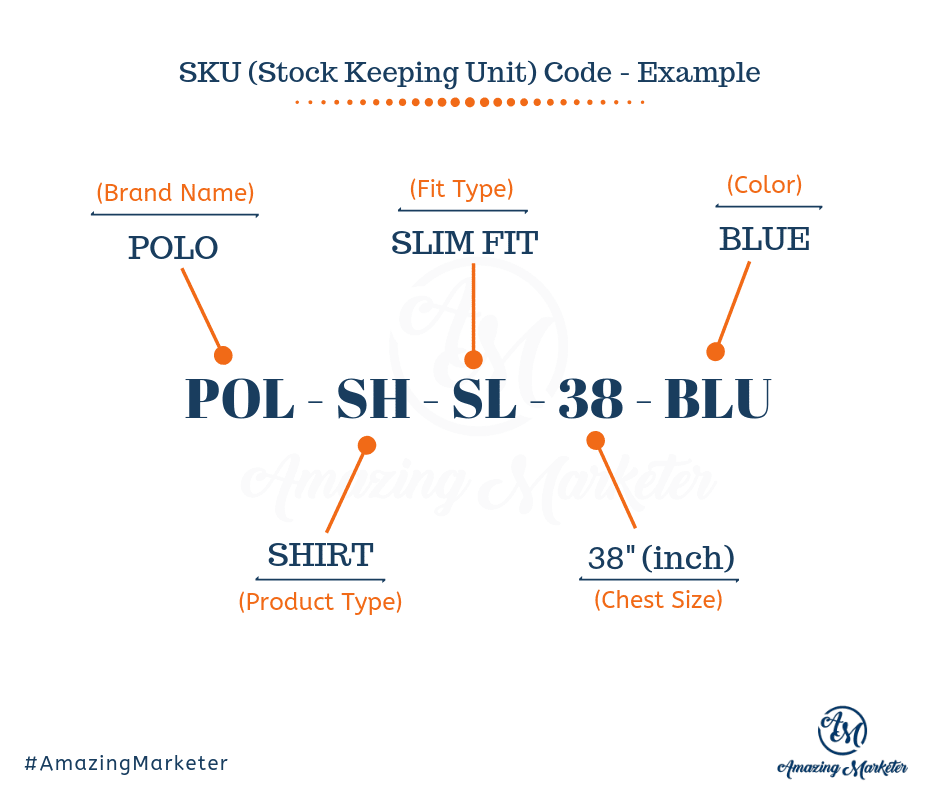

Arrange your SKUs by identifiers that allow for easy categorization. Start with top-level identifiers and then work your way down. Let’s look at the following example.

The first identifier is the brand, followed by the product type. For fashion, you could follow up with the size and color. In this example, the company has chosen to further qualify the size with “fit type.” If you segment customers by fit type, then it makes sense to include this in the SKU.

3. Use SKU Management Tools

Keeping track of SKUs is much easier when you skip the spreadsheets. Your enterprise resource platform (ERP) can integrate with SKU management. On the front lines, the warehouse management system will handle SKUs and other areas such as layout.

Other viable options are inventory management systems and product information management platforms. You only need one for SKU management, so pick the one that works best for your business.

If you have data warehouses, you can opt for something like row to column in SQL for handling historical data.

Whatever you choose, pick a tool that automatically assigns UPC barcodes to newly generated SKUs. This enables you to scan and track inventory at every step of the process.

4. Track SKU Performance With an ABC Analysis

Using your warehouse management system, it’s time to assess SKU performance. An easy method is to categorize your inventory using an ABC analysis:

- A- high-value, low-frequency items

- B- moderate-value, moderate-frequency items

- C- low-value, high-frequency items

Conducting an analysis is vital to understanding warehouse layout and storage costs. The average cost per square foot of warehouse space was $8.22 in 2023. Optimize overhead spending by stocking high-yield products.

Average Warehousing Services Costs, Pricing, Rates and Fees Summarized

| Warehousing Service Costs, Pricing, Rates and Fees | 2017 | 2018-2019 | 2020 | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|---|---|---|

| Cost Per Square Foot of Warehouse Space | $6.53 | $7.79 | $7.81 | $7.91 | $7.96 | $8.22 | $8.31 |

| Cost of Warehouse Management Staff Per Year | $47,500 | $50,500 | $52,700 | $55,800 | $52,800 | $55,057 | $57,352 |

| Cost of Warehouse Staff Per Hour | $11.44 | $13.32 | $13.47 | $14.00 | $14.97 | $15.78 | $16.95 |

| Corporate Profit % For Warehouses | 8.83% | 7.25% | 9.77% | 11.00% | 10.58% | 10.49% | 9.37% |

| What Percentage Do 3PL Warehouses Increase Pricing | 2.37% | 3.67% | 3.67% | 5.59% | 3.9% | 4.54% | 4.23% |

| Average 3PL Pick & Pack Price Per 1 Item B2C Order | $2.64 | $2.86 | $2.96 | $3.13 | $3.13 | $2.97 | $3.18 |

| Average 3PL Pick & Pack Price Per 1 Item B2B Order | $3.74 | $4.17 | $4.27 | $4.27 | $4.33 | $4.31 | $4.79 |

| Average Warehouse Storage Price Per Pallet Per Month | $13.02 | $13.20 | $14.58 | $14.79 | $16.21 | $18.30 | $20.37 |

| Average Pallet Storage Fee Per Cubic Foot Per Month | $.54 | $.495 | $.495 | $.45 | $.50 | $.55 | $.55 |

| Average Pallet Storage Fee Per Square Foot Per Month | $.88 | $.66 | $.77 | $.75 | $.91 | $1.15 | $1.22 |

| Average Pallet Storage Fee Per Bin Per Month | $2.14 | $2.85 | $3.30 | $4.07 | $3.18 | $3.20 | $2.67 |

SKU ratios and sales will also inform inventory management. You can avoid manual calculations by using the warehouse management software of your choice.

- SKU ratio – gross profit per SKU, segmented into profit ranges e.g. $0-10, $10-25, $25-50.

- Sales ratio – the percentage of SKUs sold divided by the total number of SKUs sold during a given period.

You may find that low-profit margins make up over 50% of your SKU ratio but account for much less of your revenue. In that case, it may be worth using storage for medium or higher-profit products.

5. Use Historical SKU Data to Forecast Demand

Once your strategic SKU management system is in place, it’s time to analyze the data. Your team scans barcodes that track products during receiving and fulfillment. Your POS system tracks sales and removes items from your inventory that sell online or from brick-and-mortar locations.

Warehouse management tools help you visualize data and spot trends. Data analytics solutions such as Databricks machine learning adjust predictive modeling for KPIs over time. Use this information for better demand forecasting that optimizes your inventory.

6. Set Reorder Points

A crucial aspect of demand planning is the management of your ideal stock levels. SKU movement monitors order lead times, picking times, and average order fulfillment times. Combined with POS data, you will know how quickly items shift from the warehouse to the customer. Many inventory tools set dynamic reorder points that adjust based on historical data.

7. Optimize Warehouse Layout

A survey found that delivery speed impacts buying decisions for 78% of customers. Get orders out quicker with better-picking workflows. Move your best-sellers closer to the packing or fulfillment zones. This will streamline order picking.

Again, your warehouse software should help make layout improvement painless.

Rotate old stock with a limited shelf life to the front of their product zones. Even better, you can expedite their movement by coordinating flash sales with marketing.

8. Link SKUs to Shipping and Order Fulfillment

An effective SKU management strategy doesn’t only exist inside the warehouse. SKUs with barcode scanning or RFID smart tags are the best way to monitor inventory from ordering to delivery.

SKU tracking also optimizes replenishment. It also makes it easy for you to implement live delivery tracking for your customers. Not to mention, you can quickly process returns, exchanges, and refunds.

9. Monitor, Evaluate, and Improve Continuously

Strategic SKU management isn’t a process with a beginning and end. Step away from monolithic architecture and opt for modern inventory management solutions that connect data. Use warehouse analytics and your POS data to stay on top of supply chain and market trends. If you’re using a 3PL (third-party logistics) provider, use tools to integrate their data with your systems.

Track inventory metrics such as:

- Inventory turnover

- Cost of goods sold (COGS)

- Storage per SKU

- SKU velocity – (rate products are sold)

- ABC analysis

- Stockout rates

- Fill rates

- SKU profitability

- Supplier performance

- Delivery or courier metrics

It’s Time for Strategic SKU Management

Warehouse and fulfillment processes may be conducted by your business or third-party provided. Regardless of the situation, it is up to you to plan and manage an SKU implementation.

Use warehouse management tools to streamline SKU management and optimize your storage costs. Strategic SKU management also ensures you deliver accurate orders quickly to customers.

Don’t wait around for your inventory to organize itself. Start optimizing your SKUs today!

View More

View More